In December 2021, in order to better serve customers and continuously optimize processing technology to improve the quality of KY manufacturing, Nanjing KY Chemical Equipment Co., Ltd. (hereinafter referred to as Nanjing KY) completed a technical transformation project with a total investment of over 12 million yuan. The project included the addition of more than 10 sets of CNC machining and testing equipment, including CNC thread grinding machines, dynamic beam CNC gantry milling machines, up-pulling inner spline broaching machines, gantry machining centers, flexible joint coordinate measuring machines, and laser alignment instruments.

CNC thread grinding machine

Equipped with Siemens 828D CNC system, the C-axis drive is driven by full gear transmission, which can effectively improve the processing accuracy of screw leads. It adopts dynamic and static pressure spindles (dynamic and static pressure grinding heads), and the grinding wheel speed is increased by 30%. The surface finish of threaded components is increased by 15%.

Large dynamic beam CNC gantry milling machine

The optimized third-generation HK model casting base integrated processing technology can eliminate the non-standardized processing benchmark problems of motor bases, transmission box supports, and cylinder body supports caused by different process steps. Based on this standardized casting base processing technology, the interchangeability of the core components of the double screw extruder can be realized, which can significantly improve the stability of the whole machine under high-speed operating conditions.

Large gantry machining center

The large gantry machining center is a key equipment for processing the gearbox body of the core components of the double screw extruder, and it is also one of the key newly added equipment in this project of Nanjing KY. The newly purchased large gantry machining center can complete the processing of the gearbox joint face and mounting holes at one time through process improvement and adjustment. It not only improves the processing efficiency but also eliminates positional tolerances during the processing by reducing clamping and handling times, and further improves the accuracy of the gearbox body and the assembly accuracy of the entire gearbox.

Up-pulling inner spline broaching machine

The up-pulling inner spline broaching machine is used for processing internal splines of large and medium-sized screw elements. It uses cylindrical guide pairs and has a five-point concentricity of the guide center, the cylinder center, and the broaching center with double oil cylinders, making it easier to ensure the broaching accuracy of the workpiece. It can effectively improve the surface finish of the inner splines and the perpendicularity between the splines and the end faces of the processed screw elements.

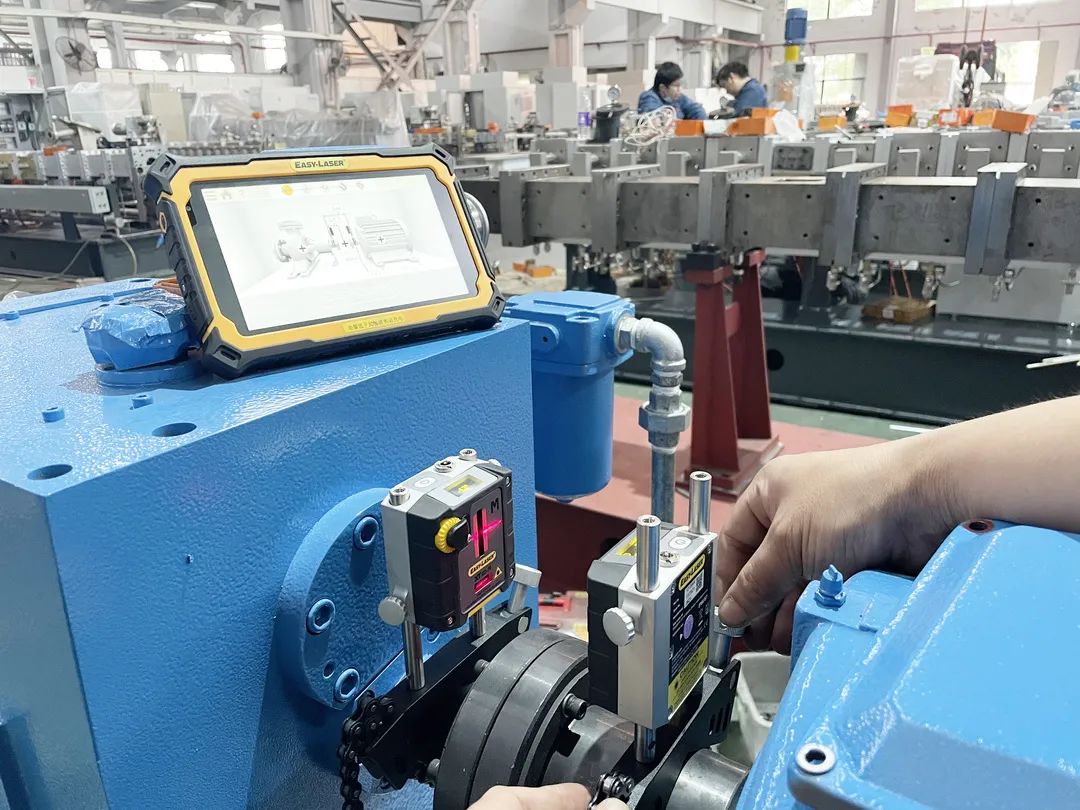

Laser alignment instrument

The laser alignment instrument is more user-friendly and visual in the overall assembly and ensures the coaxiality of the double screw extruder from the main drive motor to the gearbox and then to the entire processing section.

Flexible ioint coordinate measuring machine

The flexible joint coordinate measuring machine can detect the coaxiality of the overall machine assembly and is a critical step in achieving high-speed and continuous stable production of the entire machine. The application of new process technology is also the source of Nanjing KY's confidence in improving the performance and quality assurance of its core products.

The technological improvements that Nanjing KY has made in processing and testing equipment have given impetus to the continuous improvement of screw element processing technology, gearbox body processing and testing, and the overall machine assembly accuracy.

This "technological improvement project" is mainly used for the production and manufacturing of the third-generation HK series double screw extruder of Nanjing KY. The successful completion of the project demonstrates the diligence of all employees of Nanjing KY in seeking technological progress and technological transformation. It is also the core of Nanjing KY's assurance of stable operation of its products and a strong pillar for customers to trust Nanjing KY!

In 2022, Nanjing KY will provide technical support and product guarantee for all new and old customers with new production and processing technology and a new team image, as well as more complete after-sales service.

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China