Masterbatch refers to a concentrated substance made by resins with excessive additives. In plastic manufacturing, the initial attaching process is replaced by adding proportional masterbatches, making it efficient and more environmental friendly. Masterbatch extruder is a key equipment for producing masterbatch. It forms high-concentration masterbatch by uniformly mixing pigments, additives and base plastics and extruding them. Masterbatch is an important raw material in plastic processing. Masterbatch produced by Masterbatch extruder can significantly improve the performance and quality of plastic products.

Color masterbatch: Color masterbatch extruder machine is used to disperse pigments uniformly within a resin to create color masterbatch. The surface characteristics of pigments influence their content in the masterbatch, with organic pigments typically comprising 20% to 40% of the mass fraction, while inorganic pigments range from 50% to 80%. These color masterbatch products are versatile and can be applied in various applications, including films, cables, sheets, pipes, synthetic fibers, and most engineering plastic applications.

Functional masterbatch: Refers to the concentrate of various plastic additives. For example: pearl masterbatch, metal pigment masterbatch (for automobiles and household appliances), double anti masterbatch (for agricultural films), anti-static masterbatch (for packaging films), anti-fog masterbatch (for agricultural films), antibacterial masterbatch (for medical and daily life products, and etc.).

Flame retardant masterbatch: Masterbatch produced by mixing flame retardants and resins. Some plastics are flammable, especially those with high carbon content. This material is properly processed so it can be used in fire hazard environments. It is applied in electronics,construction, automotive,and aviation industries.

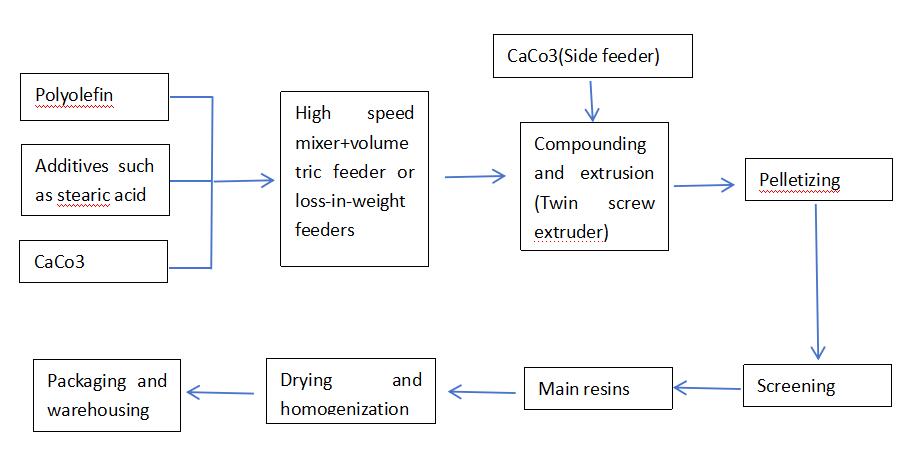

Filling masterbatch:

The polyolefin filling masterbatch consists of three parts: carrier resin, fillers, and various additives. Its performance and cost mainly depend on the carrier resin’s content, which generally contains 10% to 25%. The carrier resin should have good compatibility with the filler. Filling masterbatch can be used for processing plastic films, hollow products, pipes, sheets, injection molded products, and plastic fast food boxes. It can improve the strength, anti-aging and other properties of products and reduce costs.

Filling masterbatch, as a common masterbatch, is widely used in various film products, such as breathable films, shopping bags, and etc. The common solutions are:

Equipment parameters

Machine Model | Unit | SK63 | HK73 | SK73 |

Screw Diameter | mm | 63 | 73 | 73 |

Max. Screw Speed | rpm | 900 | 600 | 900 |

L/D | max | 52 | 52 | 52 |

Motor Power | kw | 250 | 315 | 400 |

Capacity | Kg/h | 500-900 | 700-1200 | 900-1800 |

A high-tech company in Foshan city that specializes in the production of thin film materials, including maternal and child hygiene products, medical materials, and protective products.

We have provided 3 sets of SK73 twin screw extruder production lines and 1 set of HK73 twin screw extruder production line.

A company in Jiangsu that produces polyolefin color masterbatch.

We have provided over 30 sets of HK series twin screw extruder production lines.

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China