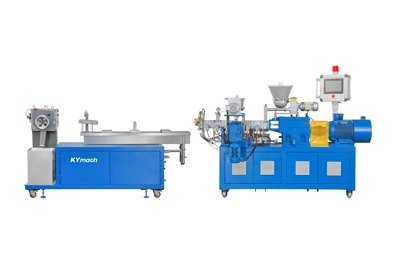

Since its establishment in 1993, KY has been devoted to the development and manufacture of small laboratory twin screw extruders. On the 9th anniversary of the introduction of HK and SK series twin-screw extruder, KY introduced two new KY-Lab Twin Screw Extruders, namely, the new high torque HK26 and the super high torque SK26, with a diameter of 26mm. The model of our laboratory extruder for sale is specially designed for universities, scientific research institutes, and R&D departments of enterprises. Our laboratory twin screw extruder fully meets the tasks of teaching, formulation R&D, proofing, and small-batch production.

KY compounding extruders are at the forefront of the polymer processing industry, offering advanced solutions for a wide range of applications. These machines are designed to meet the diverse needs of various sectors, ensuring high efficiency, precision, and reliability. Below, we delve into the key application fields of KY compounding extruders, highlighting their significance and the benefits they bring to each area.

Polymer compounding is a critical process in the production of high-performance plastic materials. KY compounding extruders are equipped with state-of-the-art polymer compounding equipment that ensures uniform mixing and dispersion of additives, fillers, and reinforcements into the polymer matrix. This results in materials with enhanced properties tailored to specific applications, such as automotive parts, consumer goods, and packaging materials.

Masterbatch production involves the creation of concentrated mixtures of pigments, additives, and other components that are later diluted into a polymer base. KY’s filler masterbatch extrusion machines are designed to handle high filler loadings and ensure consistent quality. These machines are essential for producing color masterbatches, additive masterbatches, and functional masterbatches used in various industries.

Specialty compounds require precise control over the formulation and processing conditions. KY compounding extruders, with their advanced twin screw extruder screw elements, provide the flexibility and precision needed to produce specialty compounds with specific characteristics. These compounds are used in applications such as medical devices, electronics, and high-performance engineering plastics.

In the context of sustainability, recycling and waste management have become increasingly important. KY compounding extruders play a vital role in the recycling of plastic waste, converting it into reusable materials. The machines’ robust design and efficient processing capabilities make them ideal for handling recycled polymers, ensuring high-quality output and contributing to a circular economy.

For research and development purposes, KY offers compounding extruders that are tailored to experimental and pilot-scale production. These machines allow researchers to test new formulations, optimize processing parameters, and develop innovative materials. The versatility and precision of KY’s compounding extruder machines make them indispensable tools in the R&D sector.

One of the key considerations for any manufacturing operation is cost efficiency. KY compounding extruders are designed to offer excellent performance at a competitive twin screw extruder machine price. The machines’ high throughput, energy efficiency, and low maintenance requirements contribute to reduced operational costs, making them a cost-effective solution for various compounding applications.

Nanjing KY Chemical Machinery Co., Ltd. is a professional manufacturer and supplier of twin screw extruder of lab scale. If you are interested in our laboratory twin screw extruder for sale, please feel free to contact us directly for lab scale extruder price and more detailed information.

The clearance between the screw and cylinder of KY laboratory twin screw extruder is smaller, which is convenient for discharging and cleaning.

Modular structure, interchangeable 4D/6D barrel, standard screw element design.

Reliable synchronous amplification to HK and SK series products.

Spline sleeve and nose are the new quick-opening structure, clearing and screw replacement combination is more convenient.

The cooling pipes and wiring of the whole extruder pelletizer are all inside the base, which ensures the smoothness of the base surface and is easy to clean.

With the coaxial solenoid valve imported from Germany, the response time of our laboratory twin screw extruder is reduced by 90% compared with the conventional solenoid valve. The cooling efficiency of the cylinder is higher, and the temperature control accuracy can be maintained at <1 Celsius.

Movable base. The whole lab twin screw extruder is supported by four strong universal wheels. Only one person can easily use mobile devices.

Adopt KY independent intellectual property rights KY laboratory extruder for sale smart operation system software V5.0 as the whole machine control system, combine KY and Germany Germany in respective control technology superiority, guarantees the entire machine control intellectualization and the accuracy.

As a professional extruder machine manufacturer in China, KY has professional lab extruders for sale. Feel free to contact us for lab extruder price and other information now.

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China