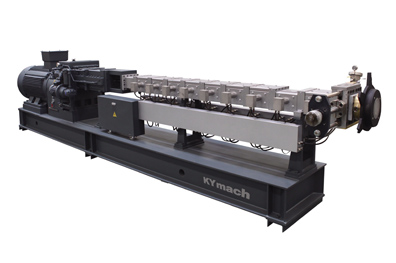

Common models such as HK63, HK73, and HK96 extruders can provide different batch production scales from 500 kg/h to 3000 kg/h. In conventional applications such as polymer blending, filling and reinforcing, these devices can provide stable output for users.

In addition to common applications, medium-sized HK extruder pelletizer also have many applications in the production of some special materials, such as TPU, bioplastics, LFT, etc. Welcome to contact KY for consultation.

In the field of engineering plastics and high filling, mass production and stability have always been the most concerning problem for users. At this time, the larger type of production equipment has become an urgent need. The equipment type of large-scale production, the diameter of KY equipment screw for selection, starts from 63 mm.

Independent research and development of high torque gearbox, gear, and bearing structure adopts the latest research results of twin-screw transmission system

Enhanced gearbox oil circuit and lubrication system of this plastic extrusion equipment for sale can still work normally under reduced flow, maintenance-free pump body long-term trouble-free, and stable operation

Highly stable safety coupling and safety interlocking system, quick disconnection of low moment of inertia, effectively protecting key components

The transmission system of HK twin screw plastic extruder also provides a good basis for high production. In addition, HK equipment upgrades the temperature control system in an all-round way, and also provides a larger vacuum exhaust system, which provides accurate temperature control and appropriate exhaust and devolatilization under the condition of super-high production, and provides conditions for stable production.

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China