Recently, the "Ringier Industrial Innovation Awards 2022 for the Plastics Industry" organized by Ringier Trade Media officially announced the winners.

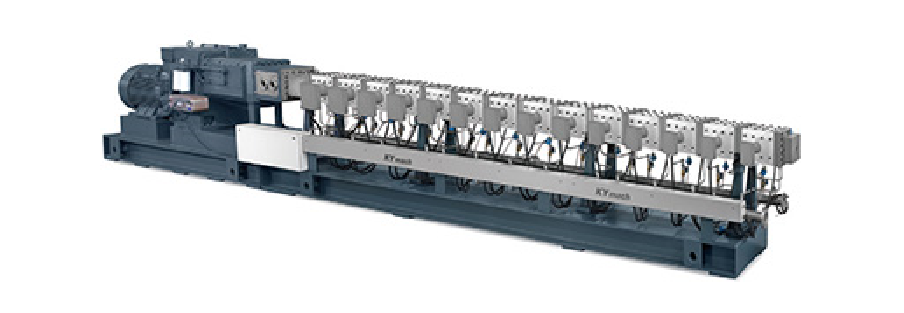

The "HKV Polymer Reaction Deep Groove Double Screw Extruder" developed by Nanjing KY Chemical Complete Equipment Co., Ltd. once again won the annual Ringier Technology Innovation Award. This honor is not only an encouragement to KY, but also once again proves the recognition and affirmation of KY's continuous innovation by customers behind the award.

The Ringier Technology Innovation Award has been held for 17 years, aiming to recognize innovative products and technologies that have made outstanding contributions to the plastic industry.

Since the successful development of the HKV series double screw extruder, KY can provide customers with equipment that can precisely meet their process requirements and can completely replace imported products.

Since the first set of HKV products were successfully developed, KY has provided a series of equipment specifications for customers from pilot to production models to meet the equipment needs of different production capacities.

At present, KY's HKV equipment has been applied to polymerization reactions of high polymers, including aramid polymerization and aramid spinning; continuous polymerization of siloxane and high-temperature nylon, as well as devolatilization and other process applications.

The potential application fields include processing of thermoplastic plastics filled, polymer devolatilization, continuous body or solution polymerization, powder coatings, food, pharmaceuticals, sealants, pet feed, stirring, dissolving, evaporation and other process applications.

The HKV series deep groove double screw extruder is designed based on Do/Di=1.8, which can increase the free volume by 35% compared with conventional extruders. The material can stay longer in the equipment and the polymerization reaction is more complete. At the same time, it can be used for reaction processing of solid-liquid materials in various forms, with high torque, uniform stay time, and good self-cleaning performance. Its application prospects are very broad.

Innovative technology application

The average shear rate of the material is smaller, so the device speed can be higher. The HKV series deep groove double screw extruder can achieve higher output and wider operating process window.

In addition, based on the larger free volume, the HKV series deep groove double screw extruder can be used in devolatilization process, with lower material filling rate and vacuum air velocity, and the process can be more stable.

Optimization of production and torque balance

The capacity of the HKV series deep groove double screw extruder reaches 11NM/cm³, optimizing the balance between production and torque and meeting the requirements of material mixing.

Modular design of processing sections for more flexible operation

Based on the modular design of the HKV series deep groove double screw extruder, different functional sections can be set at different positions of the screw to complete feeding, conveying, mixing, melting, natural venting, filling adding, vacuum venting, pressure reducing and extruding.

Traceable data for double improvement of quality and efficiency

The control system of the HKV series deep groove double screw extruder meets the requirements of high efficiency and energy saving, and the production process data is traceable, which is convenient for process optimization.

Higher economic and social benefits

Because of its smoother feeding, gentler shearing, easier venting and higher speed, the HKV series deep groove double screw extruder can provide customers with higher economic and social benefits.

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China