The trial run of SK96 double screw extruder one-step TPU sheet production line of an KEYA overseas user was successful!

As we all know, twin-screw extruder is the key equipment in the plastic polymer blending extrusion industry. It can realize the blending modification, reaction, devolatilization, extrusion, granulation and other processes of polymer. It is one of the core equipment in the plastic industry.

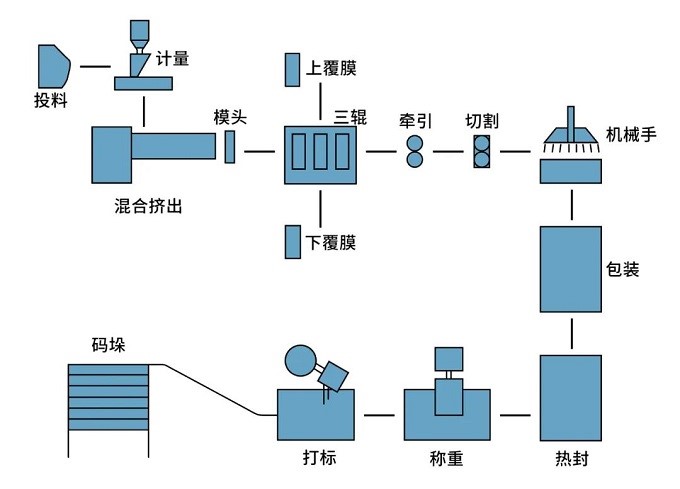

The R&D, design and manufacturing of one-step process equipment for plate and sheet production in Nanjing KEYA can be traced back to the 1990s. The SK series of the third generation twin screw extruder of Nanjing KEYA can be equipped with the whole process of material transportation, metering feeding, mixing, exhaust, extrusion calendering, upper and lower film coating, traction, cutting, manipulator grasping, heat shrinkable packaging, weighing, labeling and stacking, and a fully automated production line.

In today's environment with enhanced awareness of environmental protection and meeting the requirements of efficient production, Nanjing KEYA's third generation SK double screw extruder twin-screw one-step extrusion of plate and sheet.

double screw extruder shows obvious advantages:

1. KEYA has settled in the plastic extrusion industry for 30 years and accumulated rich material experience;

2. The third generation SK double screw extruder has high torque, high speed, high production capacity and stable and reliable operation;

3. The third generation SK twin-screw extruder realizes better mixing and exhaust effect of materials;

4. With higher surface renewal rate, the third generation SK twin-screw extruder realizes efficient reactive extrusion process and direct molding;

5. The control system of double screw extruder has strong expansibility and can meet the requirements of different users for automation degree;

6. The supporting auxiliary machines of double screw extruder have been verified by KEYA supplier access system (KAS), with reliable quality and service guarantee;

7. The efficient mixing of SK double screw extruder can save the energy consumption of material secondary heating and melting, avoid the decline of product quality caused by polymer degradation, greatly improve the production efficiency and reduce the labor cost.

The technical engineers of KEYA are tirelessly exploring the modification, granulation and extrusion technology of plastic high polymer. They are providing a broader space for users to expand upstream and downstream industries. KEYA looks forward to technical exchange and cooperation with you!

Our company is the largest manufacturer of parallel corotating double screw extruders in China and Asia, with an annual output of 250-450 sets. More than 8000 extruder systems have been installed worldwide, covering chemical, plastic, textile, food, pharmaceutical and other industries. Nanjing KEYA is customer-oriented and is familiar with the different needs of customers in various fields and industries, which will bring better service experience and create higher value for customers. Welcome to consult if you need.

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China