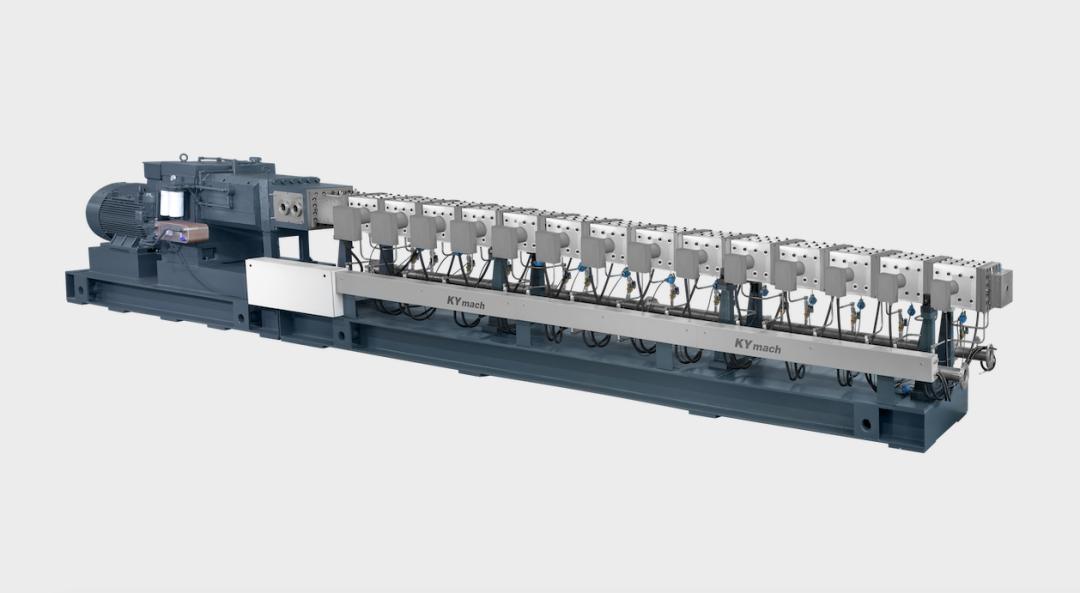

HKV Aggregation Type Deep Groove double screw extruder fills the gap in domestic aggregation type double screw extruders. Its main applications include: low energy materials processing, reaction polymerization, devolatilization, food, pharmaceuticals, and other fields.

Recently, with its innovative technology of HKV Aggregation Type Deep Groove double screw Extruder, Nanjing KY Chemical Complete Equipment Co., Ltd. ("Nanjing KY") stood out in the selection process of "2022 Plastic Industry - Ringier Technology Innovation Awards" and won the award.

A double screw extruder that meets customer needs and can produce efficiently and continuously must be a product series that has been optimized, designed, and manufactured repeatedly, and has been verified by customer processes.

Based on the screw Do/Di=1.8 design, HKV Aggregation Type Deep Groove double screw Extruder increases the free volume of the conventional model by 35%, and increases the material residence time in the equipment by 40%, providing a wider operating window for aggregation and devolatilization, and can achieve devolatilization processes with a ratio of 1% to 80% volatiles.

Moreover, the appearance of HKV Aggregation Type Deep Groove double screw extruder fills the gap in domestic aggregation type double screw extruders and can completely replace similar imported products. It is mainly used in polymerization reactions of materials such as Aramid polymerization, Aramid spinning, continuous polymerization of siloxanes, continuous polymerization of high-temperature nylon, and high-capacity devolatilization applications.

Potential application areas also include processing of thermoplastic plastics filling, continuous body or solution polymerization, powder coatings, food, pharmaceuticals, sealants, pet feed, and other processes such as material mixing, dissolving, and evaporation.

Guo Xiaochun, deputy general manager of Nanjing KY, said in an interview: "This award is a great recognition for Nanjing KY. The biggest highlight of HKV Aggregation Type Deep Groove double screw extruder is that it has a larger groove depth and a larger free volume. For downstream customers, the benefits are mainly reflected in three aspects: the single-machine output has increased by more than 50%, the single-unit energy consumption has decreased by 10% to 25%, and the product quality can be well guaranteed."

The person who goes the farthest is often the one who is willing to do and willing to take risks. The development of a new model often plays the role of "pathfinder," and it is unavoidable to face various challenges. The development of HKV Aggregation Type Deep Groove double Screw Extruder is no exception.

Since the successful development of the first set of HKV products, KY has provided a full range of equipment specifications for customers, from pilot to production models (four models with screw diameters of 55mm, 77mm, 100mm, and 140mm, respectively). KY describes the series of technical challenges they have overcome: "The breakthrough in high-performance core shaft materials and manufacturing processes must ensure machining accuracy and meet the torsional and tensile strength of the entire core shaft to ensure torque transmission; the element structure design of the deep groove screw must meet the requirements of material exchange and mixing; the heat transfer problem of material in the deep groove."

In the process of marketing, KY has sold more than ten sets of equipment, achieving good economic and social benefits.

Currently, the market demand for HKV Aggregation Type Deep Groove double screw extruder is 50-100 units per year. Looking at the future market prospects of this model, Nanjing KY believes that with the increasing customer recognition of the equipment and the continuous expansion of the application field, the market sales volume of this model will continue to rise.

The HKV Aggregation Type Deep Groove double screw extruder produced by Nanjing KY is completely domestically produced and assembled. Its unique screw design makes material feeding smoother, shearing more gentle, exhaust easier, and screw rotation faster. Consequently, it can bring good investment returns for customers. Compared with imported equipment, it has obvious advantages: shorter delivery time, more effective and timely after-sales service, and better performance-to-price ratio than the imported products!

KY has always pursued product innovation and is willing to have in-depth technical exchanges and cooperation with various industries in the modification and blending field!

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China