In the field of dual screw extruders in China, Nanjing KY Chemical Machinery Co., Ltd. (referred to as "Nanjing KY") is undoubtedly one of the most outstanding enterprises. Since its establishment in 1993, Nanjing KY has been focusing on the field of modified blending and its many related segments, and has firmly occupied a leading position in the dual-screw extrusion industry in China with its profound technical strength.

In addition to conventional polymer blending and masterbatch processing, Nanjing KY's dual screw extruders are also actively developing more special applications, including special fibers (aramid and ultra-high PE), hollow fiber membrane, rubber desulfurization, octabromine flame retardant masterbatch, EPP particle foaming automobile special materials, metal powder-filled modified materials, lithium batteries, antibacterial masterbatch, graphite and graphene, 3D printing consumables, powder coatings, one-step extrusion molding of sheet materials, composite fertilizers, kaolin, fluoroplastics, asphalt modification, liquid crystal materials, high concentration purification and dehumidification extrusion, etc.

If we look at Nanjing KY's technical strength from the equipment itself, the HK series of high-efficiency dual-screw extruders, which has a complete product range (about 8 to 10 models), is undoubtedly a highlight. HK series is currently one of the more mature third-generation dual-screw extruder products of Nanjing KY, covering almost all ranges from small laboratory models to large-scale production models. It is worth noting that Nanjing KY exclusively adopts a series of newly designed and developed screw components on the HK series models, which can meet different operating conditions and make it have a wider range of processing adaptability.

Nanjing KY is not satisfied with the achievements of the HK series products in the market. In recent years, through technical optimization, it has continuously improved the overall performance and stability of the machines. In 2019, under the background of the Internet of Everything, Nanjing KY began to think about how to develop more efficient and intelligent models, and then the SK Plus series of intelligent dual-screw extruders was born. According to reports, the flagship model SK40 Plus focuses on small-scale production of high-quality masterbatch and engineering plastics, with a production capacity of up to 500 kg/h; SK70 Plus is undoubtedly the "performance giant", not only benchmarking imported models in terms of performance parameters, but also demonstrating outstanding performance in customer application sites.

SK40 Plus is absolutely amazing in terms of configuration: it adopts a high-speed, high-torque transmission system customized by Germany's Henchel company, with screw speeds of 900 or 1200 rpm, and a specific torque of up to 15 Nm/cm3. It has also redesigned the processing section for high-quality masterbatch production, providing various specifications of screw elements, with cylinder lengths of 4D and 6D, so that process engineers can design screws to adapt to more formulations.

At the same time, SK40 Plus uses German-imported HIP powder metallurgy materials to manufacture screws and cylinders, with a smaller clearance, making it more convenient to produce high-content masterbatch. In terms of temperature control, the efficient cooling pipeline of SK40 Plus is equipped with imported COAX coaxial valves, and the cylinder adopts a brand-new radial cooling water channel design, using Japanese imported heating elements, which not only improves the temperature control efficiency but also reduces the temperature difference distribution and thermal deformation of the cylinder, avoids local shear heat and hardware wear, and improves the service life of equipment and parts.

For the requirements of masterbatch production, SK40Plus has designed a new type of head, with shorter flow channels and a double-hinge opening and closing design that can be opened and cleaned more quickly and conveniently when changing colors or materials, reducing user working hours and material waste. SK40 Plus is also equipped with side feed, side exhaust, enhanced feeding and other devices, enabling users to obtain greater output when adding large doses of color powder, carbon black or other small particle size fillers or additives.

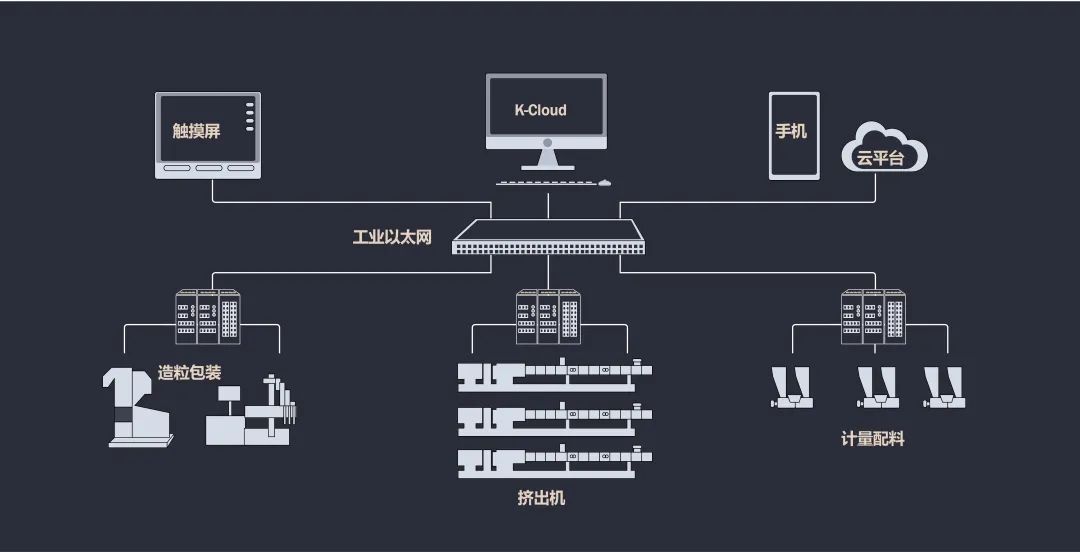

What is most critical is that SK40 Plus also adopts Nanjing KY's newly developed K-cloud control system based on mobility and interconnection, which is based on industrial IoT communication and integrates some SCADA and MES functions into the operation and monitoring system. It not only includes the control interface, process parameters and trend data recording interface commonly used by users but also expands functionally to realize equipment management, equipment OEE analysis, order management, formula management, remote maintenance, etc., which truly achieves the integration and exchange of extrusion machine production line industrialization, digitization, and informationization!

Tel: +86-25-52706155

Tel: +86-25-52706155

E-mail: info@kymach.com

E-mail: info@kymach.com

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China

No.59 West Tianyuan Road, Jiangning, Nanjing, Jiangsu Province, China